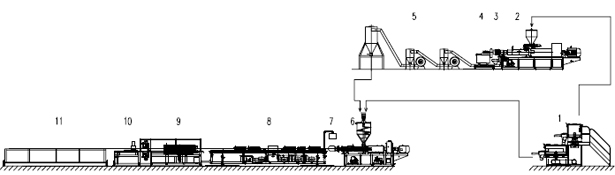

Process Flows

Plant fiber (processed) + plastic + accessory ingredient ↓high speed mixer ↓ WPC granule extrusion line

↓ WPC profiles extrusion line ↓ finished product

1. Mixing machine 2.WPC granule extruder 3.pelletizing mould 4.granule cutter 5.blower

6.WPC profiles extruder 7.mould 8.vacuum calibration unit and water cooling tank

9.hual-off machine 10.cutter 11.stacker

Technical information:

Capacity | 250kg/h |

Raw material | PVC+wood flour + other accessory ingredients |

Workshop area | ≥25M2 |

Compress air | 0.4Mpa ,0.2m⊃3;/min |

Dimension | 15m* 1.5m*1.85 m |

Power supply | 3 phase, 380 V, 50 hz |

Total Power | 85 KW |

Actual power Consumption | 80% |

Cooling Water Consumption | 1.2 ton/h |

Operator | 2 worker |